Thought this might make for an interesting topic. Too many times to count I've heard and read that spark plugs should be tightened by hand, then another 1/4 turn with socket wrench. Have any of you heard the same?

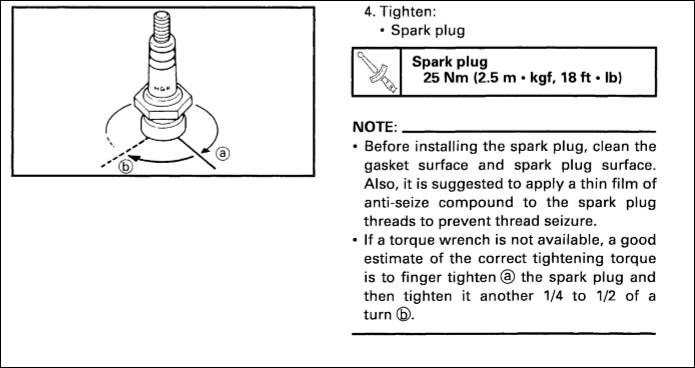

My torque wrench was readily handy from its use when torquing head bolts after replacing head gaskets last week. New plugs were also on my to-do list, so I put the hand tight plus 1/4 turn to the test. SM specs for spark plug torque is 18lb-ft.

Result:

No frickin' way is hand tight plus 1/4 turn any where close to 18lb-ft. Granted "hand tight" differs by the operators hand strength. Be that as it may, I measured 7lb-ft after hand tight plus 1/4 turn. It took another 1 1/4 turns to reach 18lb-ft of torque.

It's probable the operator will be able to make more hand revolutions of plug once the crush washer has been seated once. But I can't imagine the spec plug torque would be reached by hand plus 1/4 turn.

My torque wrench was readily handy from its use when torquing head bolts after replacing head gaskets last week. New plugs were also on my to-do list, so I put the hand tight plus 1/4 turn to the test. SM specs for spark plug torque is 18lb-ft.

Result:

No frickin' way is hand tight plus 1/4 turn any where close to 18lb-ft. Granted "hand tight" differs by the operators hand strength. Be that as it may, I measured 7lb-ft after hand tight plus 1/4 turn. It took another 1 1/4 turns to reach 18lb-ft of torque.

It's probable the operator will be able to make more hand revolutions of plug once the crush washer has been seated once. But I can't imagine the spec plug torque would be reached by hand plus 1/4 turn.

Comment