Just doing some "googling" and I came across numerous threads on various forums discussing this. An "issue" that the wallowed hole can then allow is for the pin to eventually work it's way out of the hole (at an angle, allowed by the large hole) and cause other problems such as the pin getting stuck between piston and cylinder wall, and of course causing damage and/or then allowing the rings to move, as mentioned above.

Every thread I came across said "most" 2-stroke engines use pins. I don't know if there really are any that do NOT use pins as I didn't see it mentioned. It could just be the terminology that people are using. Is there a different way to accomplish the same thing (keeping rings from moving)?

Every thread I came across said "most" 2-stroke engines use pins. I don't know if there really are any that do NOT use pins as I didn't see it mentioned. It could just be the terminology that people are using. Is there a different way to accomplish the same thing (keeping rings from moving)?

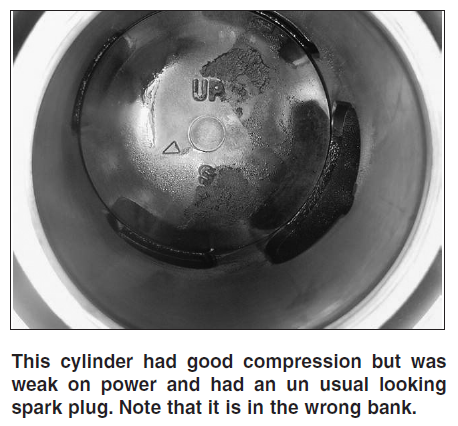

Comment