Boscoe posted, on another thread, a link to an excellent youtube vid for the speedisleeve install

https://youtu.be/p1aM0Kb9qc0

https://youtu.be/p1aM0Kb9qc0

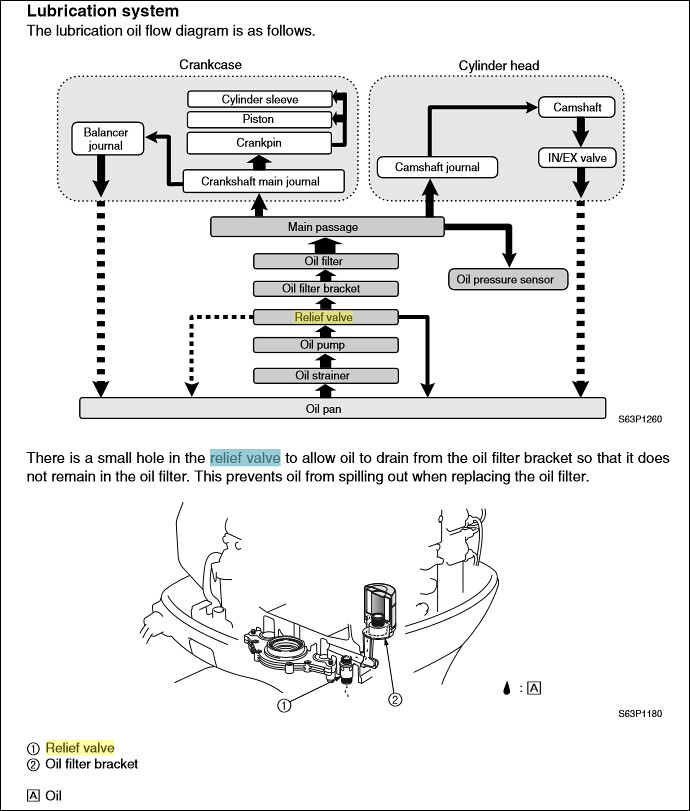

F150.LubricationCircuit by Charles Postis, on Flickr[/IMG]

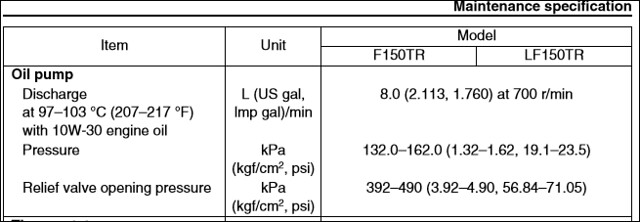

F150.LubricationCircuit by Charles Postis, on Flickr[/IMG] F150.OilPump.Specs by Charles Postis, on Flickr[/IMG]

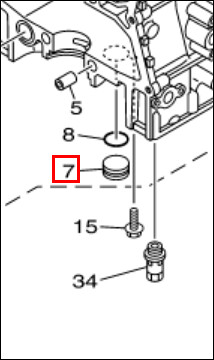

F150.OilPump.Specs by Charles Postis, on Flickr[/IMG] Plug.PRV. by Charles Postis, on Flickr[/IMG]

Plug.PRV. by Charles Postis, on Flickr[/IMG]

Comment