Quote:

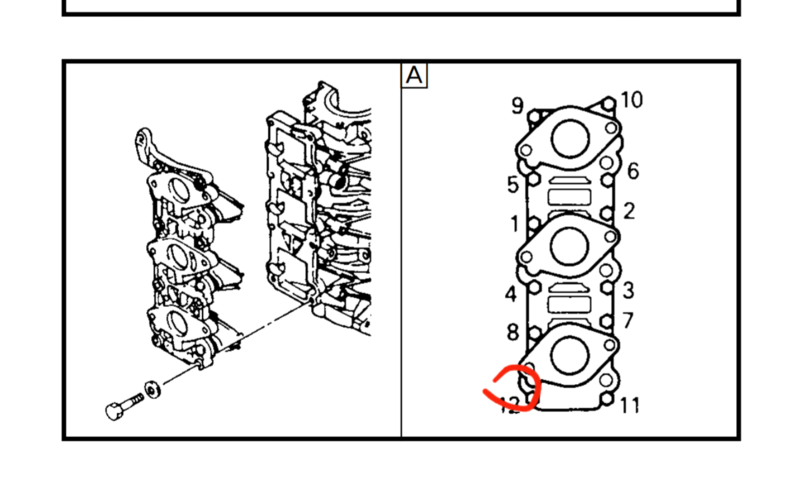

"Also noticed some arcing between the intake and crankcase but I don't think that has anything to do with my problem since I'm seeing good spark."

Where specifically?

You shouldn't be seeing ANY ARCING, PERIOD.

Can you take / post a pic pointing at where the arc is occurring?

If possible, run the engine in a DARK AREA(on muffs). Any arcing will be easier to see.

.

Your getting close...

Agreed, that isn't much leakage, but it is an air leak, leaning out that cylinder(bad).

"Also noticed some arcing between the intake and crankcase but I don't think that has anything to do with my problem since I'm seeing good spark."

Where specifically?

You shouldn't be seeing ANY ARCING, PERIOD.

Can you take / post a pic pointing at where the arc is occurring?

If possible, run the engine in a DARK AREA(on muffs). Any arcing will be easier to see.

.

Your getting close...

Agreed, that isn't much leakage, but it is an air leak, leaning out that cylinder(bad).

Comment