There are two through-hull fittings that may be in line with the intakes, but they've been there forever. I've done nothing to change that. The bottom is clean with recent anti-fouling paint.

Announcement

Collapse

No announcement yet.

F300 Overheats at high power settings but not at low to mid. What thinks you?

Collapse

X

-

1. The bottom job is old. I have not touched the bottom of the hull.

2. Just watched a few YT vids on popping the cyl heads and scraping out the crap. It just about appears inevitable. Some guys who said they routinely rinsed still had significant enough salt/sand/corrosion issues to cause overheating.

3. One guy used the flush port for the garden hose and another said he got much better results using the leg intake tube. He showed that no water came out the port side of the engine using the flush port but the water did come out when he ran it up the leg. So, we'll see how much luck I have. The schmutz collected in the bucket under the engine is pretty amazing. LOTS of crap came out of all. One guy used Rydlyme, another used water, vinegar, and Dawn dish soap. The third used diluted Muriatic acid.

Comment

-

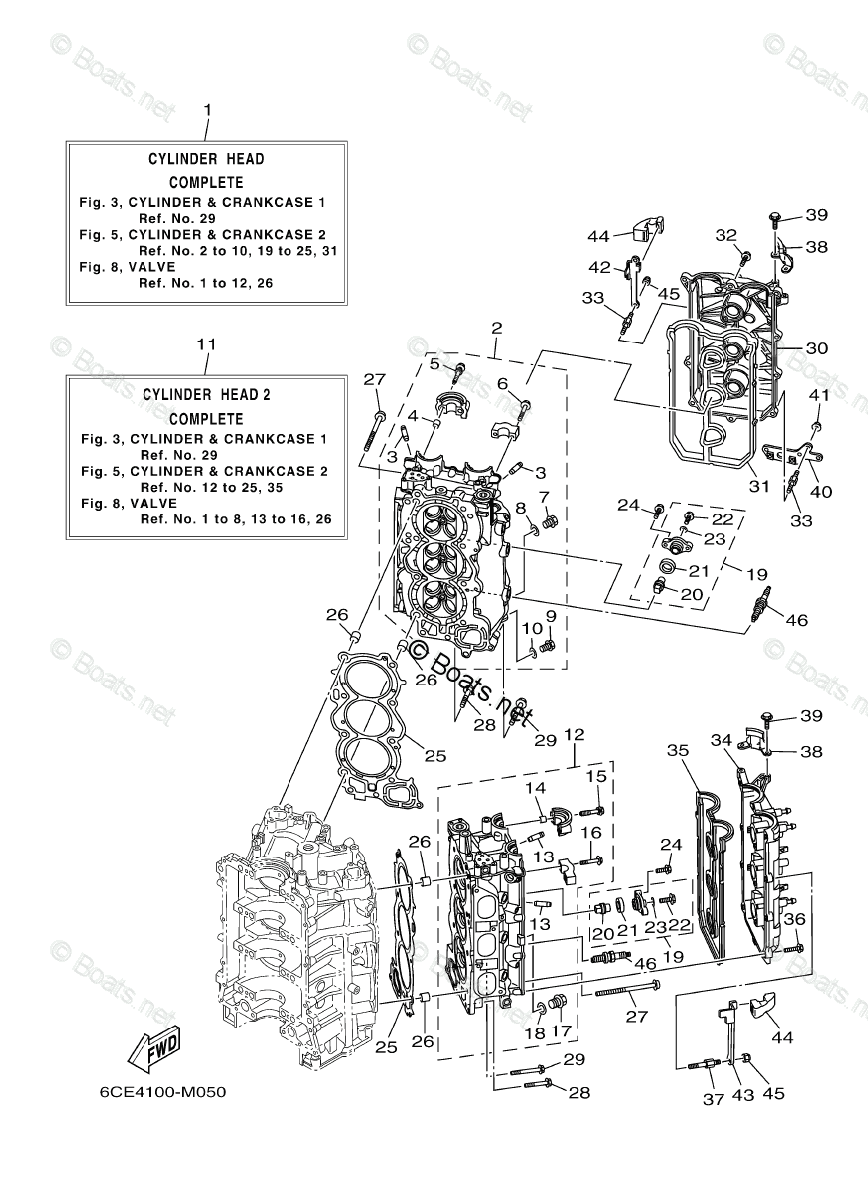

I'm looking here...https://www.boats.net/catalog/yamaha...er-crankcase-2 It looks like I need part No. 35. Or is it 31?? The last time I pulled the heads off an OB it was a 1979 OMC85. These newfangled motors mystify me.

Any opins on what solution to use? Rumor says that the number 1 ingredient in RYDLYME is muriatic acid.

Comment

-

Are you saying that you have a telltale stream at idle,Originally posted by oldmako69 View Post.. It's fine till I get it up to speed, say anything over 3300 RPM. The stream disappears and the alarm sounds.

and up to ~3300 rpm -

but then above that there is nothing coming out the telltale?

IMHO that's not an "internal blockage" issue -

that's inadequate water supply TO the block.

Have you monitored the water jacket pressure?

at idle, it will only be low single digits -

but the faster the engine runs,

the faster the water pump turns,

and volume & pressure increase output increases.

You should be seeing >15 psi in the water jacket above 3300 rpm.

A very easy way to connect a gauge

is with a garden hose adapter,

connect it to the 'flush port"

Comment

-

That is exactly correct. It pees at idle. It has adequate water PSI up to some point in the low to mid 3000s. In fact, the day it overheated the first time I was 40 miles off the beach. I found out that I could stagger the thrust of the engines and get home at speed. I can't recall the exact numbers but the PORT was at 4000 or so and the STBD (the overheater) around 2800 or so. It would not plane on one engine with 4 adults and a mess of fuel. It "sorta" would, but I felt like I was lugging the hell out of it. So coming in on one was a lousy option. With the engines staggered it kept pissing and didn't overheat. So, we were able to get home at 20-some knots vs 7 knots. I can run up and down the (no wake) creek all day with no problem.

I have not monitored the water jacket PSI. I don't have the gauge.

Comment

-

Originally posted by oldmako69 View Post1. The bottom job is old. I have not touched the bottom of the hull..how could it have recent bottom paint without touching the bottom of the hull?Originally posted by oldmako69 View PostThere are two through-hull fittings that may be in line with the intakes, but they've been there forever. I've done nothing to change that. The bottom is clean with recent anti-fouling paint.

just looking for something that has changed that might cause air to get into the cooling system at higher speeds.

that shaft and pump turning faster should pump more water,

need to find out why not enough water is flowing to keep the block filled up.

air or exhaust gasses getting in

the damper seal I was thinking about being a possible problem is 7 & 8 in this

https://cdn.boats.net/cdn-cgi/image/...2-4899f5f5.pngLast edited by 99yam40; 03-13-2022, 04:15 PM.

Comment

-

I'll clarify. The bottom paint was brand new when I bought the boat in August 2020. It has not been touched since then. The boat lives on its trailer 95 percent of the time. I've put approx 100 hours on it since then. This problem surfaced last fall. I limped home and replaced the water pump impeller and gaskets. I couldn't find anything wrong except for the gasket (Rubber O ring) that fits in the precut groove in the water pump housing...part No. 17 in 99yam40's link. I was optimistic that was the culprit. Nope.

The damper seal you speak of appeared to be in fine condition when I did the pump.

Neither engine pees worth a damn, even with new pumps. Yes, there's a stream but hardly what I would call much of one. I am inclined to think (worry) that my cylinder head water passages are partially clogged. I've watched several vids on YT this week that show remarkable levels of clogging on engines which the owner claims were "regularly flushed".

So before I tear into it and run the risk of busting stuff I am going to -

1) Pop the cowlings off and back it down the ramp. I'll fire them up and bring them up to operating temp at a fast idle. Let's say 1500-1800 or so. I'll then take a temp gun and shoot both cylinder banks on both engines, recording the temps.

It may be, there is an immediate and obvious difference between the two engines, or between one side of the "hot" engine and the other side.

2) Then I'll run the "magic juice" through the engine for an hour or 3. HOPEFULLY, I'll wind up with a bucket of sand and crud.

Then repeat step one and see if I can come up with significantly different numbers. After that, I'll just have to start tearing into it looking for blockage.

Comment

-

-

as was said before, if there was a restriction to just the water flow thru the motor, the Tell tail would not stop, it would continue peeing like it was at lower RPM

yes a reduce water flow would cause an over heat, but it would not stop the Tell tail from flowing

it sounds like the flow of water is being reduced to the point of the block not being filled up with water

either the water pump is pumping some air or exhaust gases included instead of solid water or compression from cylinders or exhaust gases are entering the cooling chambers and keeping the water from filling the block

Comment

-

OK. So for a dim-bulb shade tree wrencher....how do I determine if "compression from the cylinders or exhaust gasses are entering the cooling chambers?" Where would you start? Compression test? If I have 6 good values, it's got to rule out compression, right? And if it does, then what? How would I determine if it was exhaust without tearing the motor down to bits? I can scope the leg I suppose.

Not trying to be obtuse, I really am that dense.

Thanks.Last edited by oldmako69; 03-13-2022, 08:57 PM.

Comment

-

I would think leak down test of the cylinders should show if the heads or head gaskets are leaking into the cooling system, but you may have to pull the stat covers to hear it.

but I have no idea how you could prove any thing else.

it just does not make sense to me how restricted cooling passages would starve the tell tail at a higher RPM is the pump is pumping a lot of water.

should pump enough to open the poppit to dump excess water/pressure

could a test prop be installed to load up the motor without it flying across the water maybe?( sitting on the trailer)

I am not sure what RPM s you could get to with a test prop. a good Yanaha shop might know that

you could eliminate sucking air from hull disturbance that way

but I guess exhaust gasses will still be around the water intakes when coming out the prop hub area

Comment

-

The engine had 800 hours on it when I bought it. I have no idea what kind of treatment it received before I bought it two years ago. I'd guess that I have put about 150 hours on it with zero issues. IOW, no blown impeller. PRV?

I replaced the water pump kit when I had it apart last fall.

Comment

Comment