The wire on my F150 is stainless with black insulation. The insulation is what melted and probably looks like corrosion. The plastic cover would have to be removed to get to one end of that wire to unscrew and replace. Maybe Fairdeal would know how difficult it may be to remove that cover.

Announcement

Collapse

No announcement yet.

Help! Burnt wire!

Collapse

X

-

Connected to a mounting bolt. Might be fun.

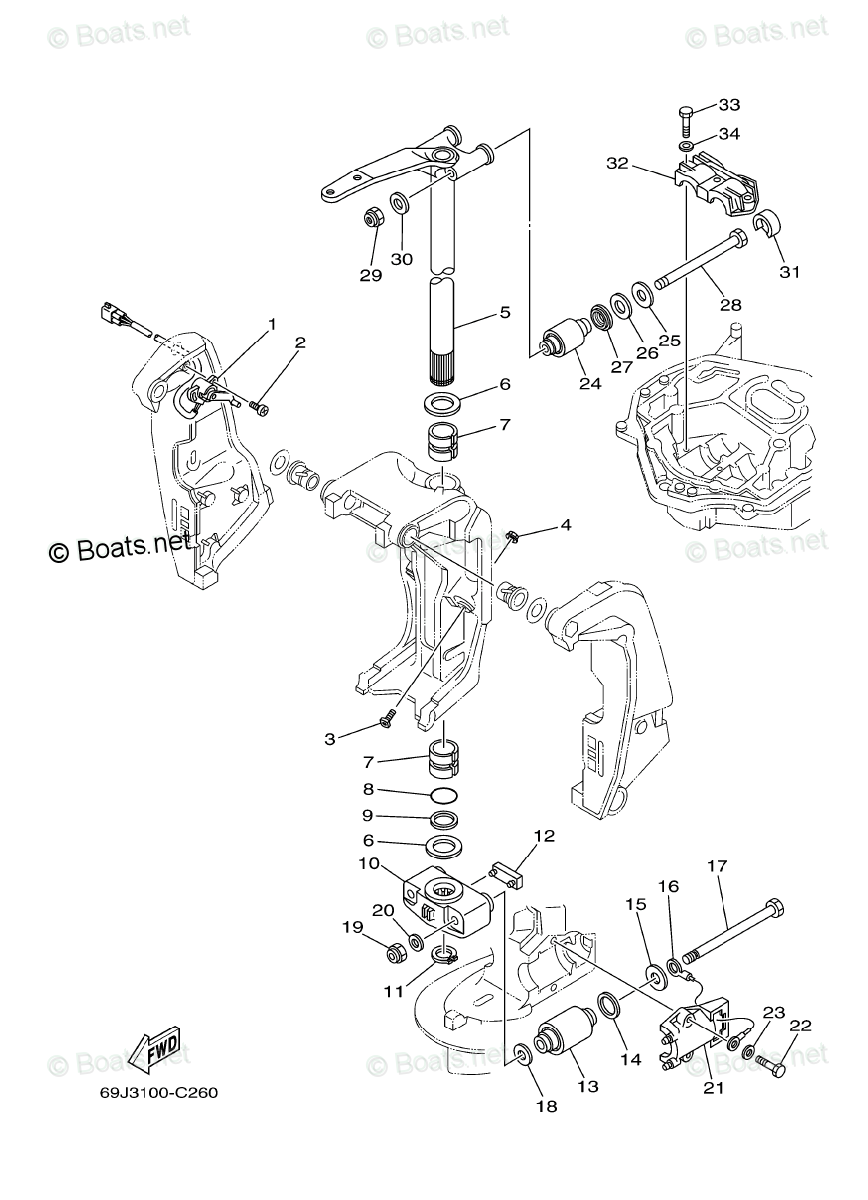

picture and diagram comparison is confusing. Looks like the hole is on front of mid section in pic.Last edited by pstephens46; 04-15-2019, 11:22 AM.

Comment

-

Simply take a razor blade and clean that damaged heat shrink off of the wire. Go ahead and run like that with decorative cover removed. It is merely cosmetic as this is a stainless steel bonding wire that is connected to everything, so no insulation is required.

The real question that all should be asking is what /where did that amount of current come from that caused such a relatively large wire to heat up to the point that it melted the insulation..... Especially since the parts connected by that wire are already connected by mechanical continuity through the bolts and metal metal contact.

Interesting.If its got teats or tires, you bound to have trouble with it....

Comment

-

I think more than the insulation is damaged. I would say the wire is now brittle and resistive, and will break easily.

There are a number ways to lay a wire from the top to the bottom and between. Just need to find suitable exposed accessible bolts, the wire(s) perhaps threaded through to hide them a bit.

The insulation may be important to stop electrolysis occurring where it may touch aluminium.Last edited by zenoahphobic; 04-15-2019, 06:40 PM.

Comment

-

Thanks to all for your input. As I'm not mechanically minded and new to boating I have to trust in the professionals at the boat shop. I didn't pick the boat up myself as I was working remote and only noticed the wire hadnt be replaced after I got back from my swing. The boat shop was told when I dropped it off that was my priority.

Comment

-

Originally posted by zenoahphobic View PostI think more than the insulation is damaged. I would say the wire is now brittle and resistive, and will break easily.

There are a number ways to lay a wire from the top to the bottom and between. Just need to find suitable exposed accessible bolts, the wire(s) perhaps threaded through to hide them a bit.

The insulation may be important to stop electrolysis occurring where it may touch aluminium.

it bolts/ties to the different aluminum parts to bond them together so the anode can protect them, so I do no think the bare wire touching aluminum parts would hurt anything.

I would be asking them what caused it and why they did not address that wire after you asked them to.

I am at a loss as to how the pump going bad could cause this wire to heat up

Comment

-

Looking at those photos again, that hole does look strange, the size of it and the many lines like guilding evenly spaced all around.

I don't think that wire could have flexed so evenly around like that?

I wonder if you can see through it where it is bolted? You could clean that hole smooth and round and perhaps get to that bolt to at least replace from that end. I wonder whether someone had already applied some "handy wook" contributing to this?

My imaginative mind takes me to many places, can't stop thinking about the markings around that "burnt" hole.🤔🤔

Comment

-

I just reviewed this again, yes, from the first post's pictures, this wire was hot either for quite a while during multiple orientations as the vessel was being run, to cause that many 'hot melt' moments OR, there were multiple moments where it got instantaneously red hot... In a multitude of orientations

I do not see where the OP BingoBongo posted what year/model this engine is, so I am limited at researching online or manual.

This is super curious, as if this is the bonding wire I think it is, it would have been submerged, and that would mean it would have had to have been super hot!If its got teats or tires, you bound to have trouble with it....

Comment

-

I'm with you. This is worth getting 60 Minutes to investigate! Maybe down the track we can make a Hollywood Production, I can see Oscar's, this mystery is greater than Twin Peaks🙂🙂🙂🙂🙂Originally posted by FabricGATOR View PostI just reviewed this again, yes, from the first post's pictures, this wire was hot either for quite a while during multiple orientations as the vessel was being run, to cause that many 'hot melt' moments OR, there were multiple moments where it got instantaneously red hot... In a multitude of orientations

I do not see where the OP BingoBongo posted what year/model this engine is, so I am limited at researching online or manual.

This is super curious, as if this is the bonding wire I think it is, it would have been submerged, and that would mean it would have had to have been super hot!

Comment

-

the amount of misinformation is growing.

that wire is not brittle and will not break.

the plastic covering is simply cosmetic.

you have a ground wire issue.

you DO NOT have a short.

the batteries were NOT hooked up backwards,you did not blow the 60 amp fuse.

it is simply a bonding wire.

holds isolated parts at the same electrical potential.

that is all it does.

Comment

-

this particular wire connects the swivel bracket to the lower casingOriginally posted by rodbolt17 View Postyou have a ground wire issue.

you DO NOT have a short.

so that it is electrically continuous with the powerhead

there is another wire at the top of the swivel bracket that connects to the port side bracket

and another from the bottom of the port side bracket to the t/t unit

(the latter seems superfluous,

given the intimate mechanical connection between the t/t unit and the brackets)

I can't imagine a circumstance where battery power would "return to ground"

through that bonding wire -

other than an internal short to the housing of the t/t motor.

And even that seems implausible.

Comment

Comment